SOLUTIONS

SOLUTIONS

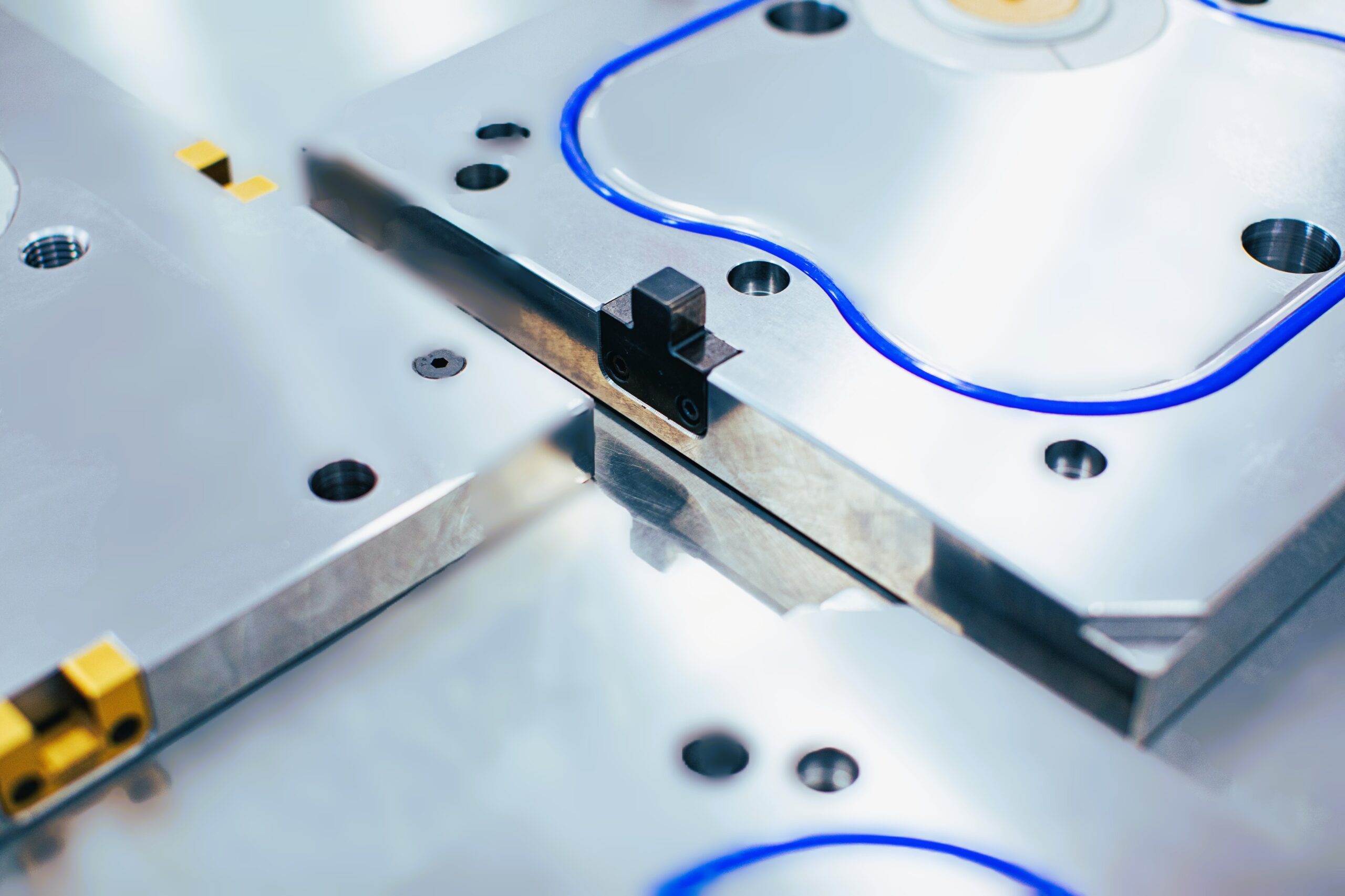

Liquid Silicone Manufacturing

Company

Lim-US is a Wisconsin based technical manufacturer of precision silicone products, founded and operated by an engineering and operations professional, with a broad commercial background, and over 25 years of experience with silicone elastomers.

We are both an agile and engineering led business that provides best practice silicone solutions adapted for tomorrow’s challenges, developing and producing polymer-based products from concept development, product design and process optimization, to low and high-volume production, post-processing, assembly and logistics.

Data Led, Lean, and Process Driven

Our Philosophy

LIM US is a reliable, service focused, and collaborative resource that develops strong partnerships through providing innovative solutions from our experience and expertise of engineering and manufacturing in silicone injection molding and extrusion markets.

‘We are agile problem solvers that get our customers to market faster and help them create their competitive advantage.’ -Michael O’Hara, Founder

Engineering integrity for critical end use applications

Industries

Healthcare

Industrial

Energy

Automotive

Aerospace

Electronics

Our Services

Technical Capabilities

Fast Turnaround Soft Tooling Options for Testing or Design Verification, Form, Fit & Function, Automation/Pilot Sampling

15cm^3- 28cm^3 repeatable injection shot volume range (+/- 0.02g/unit) (55t IMM)

Clean, Bright, White, and Visual Manufacturing Space. Lean Systems / Continuous Improvement focused.

Launch & Interim production for pre ramping volumes

IQOQPQ, PPAP. Six Sigma Black Belt, Statistical Regression Techniques (DOE, ANOVA (Normal/Non-Normal), Pearson Correlation)

Dispersed or Brush/Dip Adhesion Promoters for Thermoplastic and Steel substrates.

Serial production and fully automated production capabilities.

Reliable, Repeatable, Robust- SIM (Scientific Injection Molding) Techniques

55t -120t Arburg/Engel IMM’s, Elmet (Flow Controlled) Silicone Dosing/Pump Technology.

2x 20t Transfer LSR/HCR Silicone

2.5” (Dia.) Standard Davis Extruder HCR Silicone

Assembly

Clean

Packaging

Slitting, Cutting or other

Sodick Sinker & Wire EDM

HURCO CNC Machining Centers

LIM US sources LSR with the world’s main suppliers, including Elkem, Wacker, ShinEtsu and Dow

Engineers and product designers can fully leverage LSR’s broad material properties to create resilient and reliable products.

Silicone Elastomer Solutions

LSR is a viscous liquid and classified as a two-part heat cure, or addition reaction, high-performance thermoset elastomer. Its main differentiating characteristics are excellent compression set, biocompatibility, chemical resistance or inertness, and broad functional stability to service temperatures of 250C (480F).

“Silicones Drive Innovation”

Multifunctional Performance